National Standard of Recyclable manufacturing scraps of Neodymium Iron Boron (NdFeB)

Standard interpretation

1. The background of standard setting

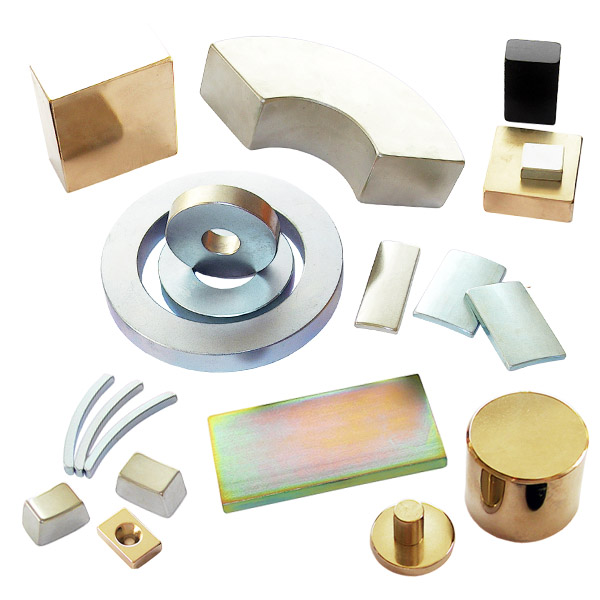

NdFeB permanent magnet material is an intermetallic compound formed by rare earth metal element neodymium and iron element. It has excellent magnetic properties and is one of the most important rare earth functional materials. In recent years, the application field of NdFeB permanent magnet materials has become more and more extensive. It has expanded from the original aviation, aerospace, navigation, weapons and other defense and military fields to instruments, meters, energy and transportation, medical equipment, electronic power, communications, etc. The civilian high-tech field.

Since different application fields have different requirements for the shape of NdFeB permanent magnet materials, the production of NdFeB permanent magnet materials in my country is first processed into blanks with the same shape, and then according to the needs of users, through mechanical processing to obtain different types Finished product. In the production and processing of NdFeB permanent magnet materials, a large amount of machining debris, leftovers and sludge debris will be produced, and there are also raw materials remaining in the process of grinding, pressing, and roasting. These wastes are neodymium iron. Boron production and processing recycled materials account for about 20% to 50% of the amount of NdFeB blanks, which is also generally referred to as NdFeB scrap in the industry. Such recycled materials will be collected separately, most of which will be purchased by rare earth smelting and separation plants, and recycled into rare earth metals, which will be used again in the production of neodymium iron boron materials.

With the development of the NdFeB industry, the categories of NdFeB permanent magnet materials are more abundant, and the specifications are also increasing. There are varieties with high content of cerium, holmium, terbium, and dysprosium. The corresponding NdFeB production and processing materials contain cerium The content of, holmium, terbium, and dysprosium has also increased, leading to greater changes in the total amount of rare earths and the proportion of rare earth elements in the NdFeB production and processing materials. At the same time, with the increase in the trading volume of recycled materials, the phenomenon of shoddy and fake materials appeared in the transaction process. The types of recycled materials need to be more detailed, and the methods of taking and preparing samples need to be more clarified, standardizing acceptance conditions, and reducing trade. dispute. It has been more than ten years since the original standard GB/T 23588-2009 "NdFeB Scrap" was released, and its technical content is no longer suitable for the needs of the current market.

2. The main content of the standard

The standard stipulates the classification principles, chemical composition requirements, test methods, inspection rules and packaging, marking, transportation, storage and quality certificates of NdFeB production and processing recycled materials. It is applicable to the production and processing of NdFeB Recycling, processing and trading of various types of recyclable waste (hereinafter referred to as recycled materials). In the process of compilation, through extensive investigations, and after many expert discussions, the opinions of various NdFeB manufacturers, NdFeB product application companies and rare earth separation companies in my country in recent years have been listened to, and the key technical content of the revision of this standard has been clarified. In the standard revision process, the classification was further divided according to the source process of the recycled materials, the appearance and chemical composition of various recycled materials were described in detail, and the classification basis was listed to provide a technical basis for the trading of recycled materials.

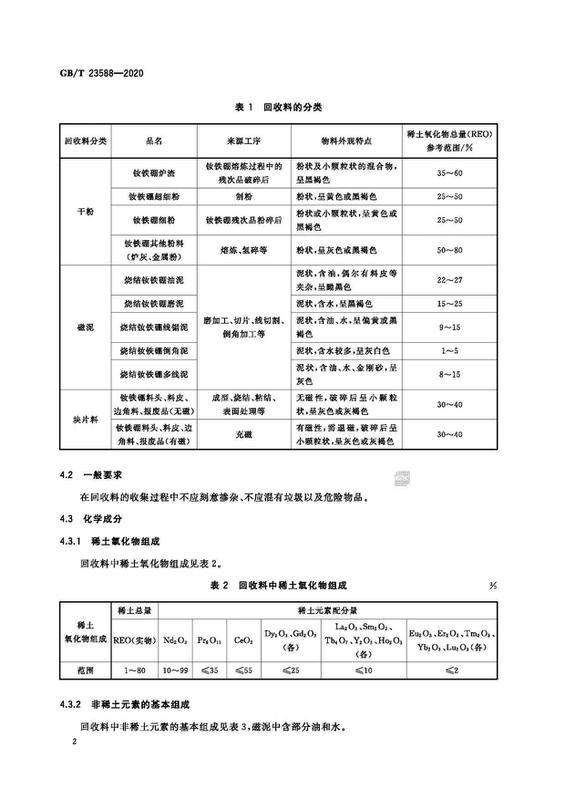

Regarding the classification of recycled materials, the standard clarifies the three major categories of dry powder, magnetic mud, and block materials. In each category, the appearance characteristics of the materials are subdivided according to the source process. In the trading process of recycled materials, the total amount of rare earth oxides and the proportion of each rare earth element are particularly critical pricing indicators. Therefore, the standard lists the total amount of rare earth elements, proportions, and non-rare earth elements in the recycled materials. surface. At the same time, the standard provides detailed regulations on the sampling methods, tools, and sampling ratios of recycled materials. Because the recycled materials are often uneven, in order to obtain a representative sample, this standard specifies the requirements for the selection of sampling points and sample preparation methods for the specifications of inserts used in sampling.

3. Significance of standard implementation

my country's NdFeB production and processing produces a large amount of recycled materials, which is a characteristic product of my country's NdFeB permanent magnet material industry. From the perspective of resource recycling, NdFeB production and processing recycled materials are extremely valuable renewable resources. If they are not recycled, it will cause the waste of precious rare earth resources and huge environmental hazards. In order to reduce the environmental harm caused by rare earth mining, my country has always implemented strict rare earth production quota control and controlled the mining of rare earth mines. NdFeB production and processing recycled materials have become one of the important raw material sources for my country's rare earth smelting and separation enterprises. Throughout the production and supply chain of rare earth to NdFeB permanent magnet materials in my country, rare earth elements are fully recycled, with a recovery rate of nearly 100%, effectively avoiding the waste of high-value rare earth elements, and making my country's NdFeB permanent magnet materials international More competitive in the market. The revision and implementation of the national standard "NdFeB Production and Processing Recycled Materials" is conducive to standardizing the classification, recycling and trade of NdFeB production and processing recycled materials, and is conducive to the recycling and utilization of my country's rare earth resources, reducing resource consumption, and reducing environmental hazards. After the implementation, it is expected to bring good economic benefits and social value, and effectively contribute to the sustained and healthy development of China's country's rare earth industry!