Properties of hot-pressed and hot-deformed NdFeB magnets

Hot-pressed and thermally deformed NdFeB magnets are almost simultaneously researched and developed successfully with sintered NdFeB magnets. In 1985, the General Motors Company (GM) Research Center reported that the rapid quenching of NdFeB magnetic powder was pressed under 700℃ argon atmosphere by hot pressing technology, and a solid density isotropic magnet was obtained, which was later called MQ-Ⅱ magnet. ; If the isotropic solid-density magnet is subjected to thermal deformation processing, that is, the MQ-Ⅱ magnet is thermally upset to less than 50% of the original height above 700 ℃, and the easy magnetization axis can reach more than 75% in the upsetting direction Orientation degree, made into a real-density anisotropic thermally deformed magnet, these three types of magnets are called MQ-Ⅲ.

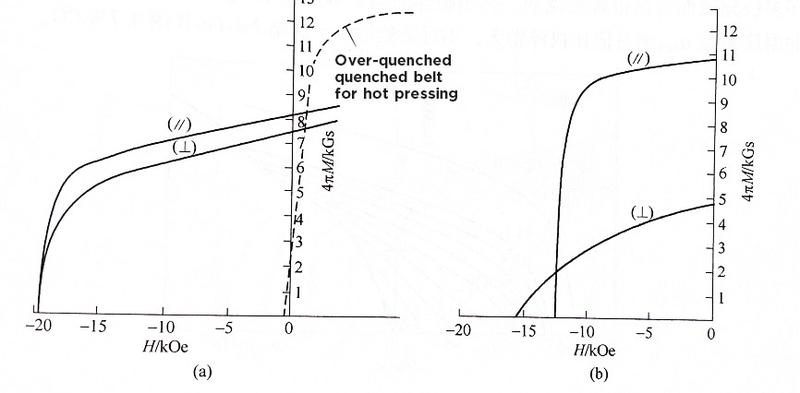

The following figure shows the demagnetization curve of high quenching speed (over quenching) Nd0.13(Fe0.95B0.05)0.87 fast quenching powder, MQ-Ⅱ magnet, MQ-Ⅲ magnet, in which the pressing direction (∥) and perpendicular to the pressing direction (⊥) The difference between the measured curves can reflect the orientation of the magnet. Obviously, the difference between the two directions of MQ-Ⅱ is not big, but there are still some orientations, while MQ-Ⅲ shows a strong orientation. Characteristically, the demagnetization curve in the pressing direction (∥) is very close to the square of the sintered NdFeB magnet, while maintaining a large remanence perpendicular to the pressing direction (⊥) indicates insufficient orientation.

Demagnetization curves of high quenching speed and rapid quenching powder and MQ-Ⅱ(a), MQ-Ⅲ(b) in the pressing direction (II) and vertical direction (T)

Because the hot pressing and thermal deformation temperature is not high, and the action time is not long, the fine grain (nano or sub-micron) structure of the fast-quenched NdFeB magnetic powder is basically maintained, so the MQ-Ⅱ and MQ-Ⅲ magnets still have a high HcJ, especially the HcJ of MQ-Ⅱ, is only 1~2kOe lower than the original powder. After a long period of time, GM Company was producing MQ-Ⅱ and MQ-Ⅲ magnets. Until the beginning of the 21st century, they transferred the production of fast-quenched NdFeB magnet powder to Tianjin, and moved the production lines of MQ-Ⅱ and MQ-Ⅲ magnets to Tianjin. Production was discontinued shortly after Mexico.

In the process of research and development of hot pressing and thermal deformation technology, Datong Electronics, a subsidiary of Japan's Datong Steel, has maintained a close cooperative relationship with GM's Magquesque Corporation (MQI). This relationship has not changed hands because of MQI several times. However, they changed their own brand NEOQUENCH-H and NEOQUENCH-D products to the market in 1991, corresponding to MQ-Ⅱ and MQ-Ⅲ, and they are still in mass production. In 1992, they put hot-press-back extrusion. The radiation-oriented magnetic ring produced by this method is marketed under the trade name NEOQUENCH-RD. This is a key component needed for precision permanent magnet motors and has broad development prospects.