Do you know new SmFeN samarium iron nitrogen rare earth permanent magnet material?

As the third generation rare earth permanent magnet material, NdFeB magnets have been widely used due to their excellent magnetic properties. However, NdFeB magnets also have shortcomings such as low Curie temperature, large coercive force temperature coefficient and poor chemical stability, and The huge consumption of praseodymium, neodymium, dysprosium and terbium rare earth resources has caused people to worry about environmental damage and the sustainability of rare earth resources. Therefore, while magnetic material practitioners continue to improve the performance of NdFeB permanent magnet materials, they are also Actively develop other new permanent magnet materials.

In 1990, Professor Coey from Ireland used gas-solid phase reaction to synthesize RE2Fe17Nx interstitial intermetallic compounds. Through research, he found that Sm2Fe17Nx compounds have excellent intrinsic magnetic properties, announcing the birth of SmFeN rare earth permanent magnet materials. The theoretical maximum magnetic energy product of samarium iron nitrogen permanent magnets reaches 62MGOe (slightly lower than Nd2Fe14B, 64MGOe), and its coercive force and Curie temperature are much higher than that of NdFeB, and can be more widely used in high-temperature environments such as motors.

| Magnet type | Curie temperature(℃) | saturation magnetization μ0Ms(T) | Magnetocrystalline Anisotropy Field μ0Ha(T) | Maximum magnetic energy BHmax(kJ/m3) |

| Sm2Fe17Nx | 476 | 1.57 | 15.6 | 470 |

| Nd2Fe14B | 307 | 1.61 | 8.0 | 516 |

In addition to excellent comprehensive magnetic properties, samarium iron nitrogen has good corrosion resistance and oxidation resistance, and does not contain strategic metal elements compared to samarium cobalt; compared with neodymium iron boron, there is no need to consume expensive rare earths such as praseodymium, neodymium, dysprosium, and terbium. elements (samarium element content is relatively large and the price is not high), it fully meets the conditions for becoming a new permanent magnet material. The attractive prospect made samarium iron nitrogen once the hottest topic in the research and development of permanent magnet materials. Since the discovery of Sm2Fe17Nx series rare earth permanent magnet materials by Coey et al., there has been a rapid upsurge in researching Sm2Fe17Nx series permanent magnet materials around the world. At that time, hundreds of laboratories around the world were involved in research in this area. However, a series of subsequent experiments proved that this permanent magnet material was not successful on the road to industrialization, and research was hot and cold.

In recent years, with the rapid development of the automobile industry and the miniaturization and lightweight of electronic appliances, people have put forward higher environmental operating temperature and magnetic performance requirements for permanent magnets. Sm2Fe17Nx series rare earth permanent magnet materials have both good temperature and The potential application value of permanent magnet materials with stability and excellent magnetic properties has once again attracted people's attention, and Sm2Fe17Nx series permanent magnet materials have also ushered in a new research and development boom. Due to the price increase caused by the large-scale development and use of rare earths, the price increase of Nd has led to an increase in the cost of producing Nd-Fe-B, while the rare earth Sm is in a state of relative surplus. The development of Sm-Fe-N is conducive to reducing costs and strengthening the comprehensive utilization of rare earth resources. . Therefore, Sm-Fe-N is likely to replace Nd-Fe-B, both in terms of magnetic properties and production cost, and become the fourth-generation rare earth permanent magnet material that people are looking forward to.

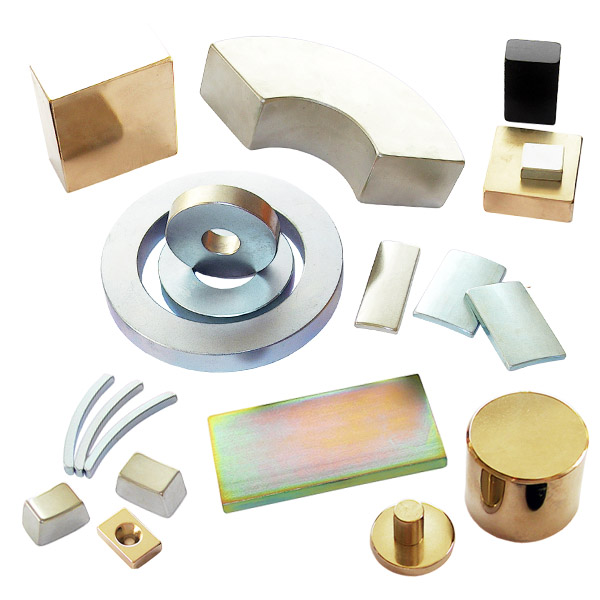

After more than 20 years of research and exploration, the problem of industrial large-scale production of Sm-Fe-N has not yet been solved. The study found that Sm-Fe-N decomposes into SmN and Fe at temperatures above 873K and loses its permanent magnetic properties. To a great extent, its application in sintered magnets is limited. Sm-Fe-N can currently only prepare injection molded magnets, bonded magnets and rubber magnets. Initially, organic substances such as nylon and epoxy resin were used as binders. Since these binders can only be used below 200°C, they cannot be used to their full potential. Sm2Fe17Nx has the advantage of good high-temperature performance, so how to make breakthroughs in technology and whether it can develop new binders are the key to the competition between Sm2Fe17Nx magnets and Nd-Fe-B magnets. In recent years, some low-melting-point metals have begun to receive widespread attention. People use low-melting-point metals such as Zn and Sn as binders. However, because low-melting-point metals such as Zn are used as binders, they will reduce the saturation magnetization intensity, thus leading to (BH) max is lower. It can be seen that in order to give full play to the performance of Sm2Fe17Nx, it is crucial to find a good binder. At the same time, the preparation of Sm2Fe17Nx densified magnets is still pursued by scientific researchers, because densified magnets can better exhibit theoretical magnetic properties.

According to statistics from the Japan Bonded Magnet Association, based on the performance advantages of samarium iron nitrogen magnetic materials such as high magnetic properties, high corrosion resistance, high temperature demagnetization resistance and good forming freedom, its application directions are mainly in information communications, industrial production, and household electronics. As well as automotive and other fields, including speakers/speakers, camera shutter motors, spindle motors, disk adsorption, magnetic rollers, fan motors, linear engines, fully automatic machinery and equipment, high-speed motors, air conditioners, household motors, magnetic sensors, pumps, auxiliary machinery, etc. .

At present, Sm2Fe17Nx has made great progress in the preparation and application of bonded magnets, but densification is still a goal pursued and struggled by many magnetic material workers. Once a suitable preparation process is developed, it will be possible to achieve it. Theoretical magnetic properties accelerate the commercialization process of samarium iron nitrogen magnets.