Item No.: NdFeB-2

Rare Earth NdFeB Magnet

Professional Rare Earth Magnet and NdFeB Magnet manufacturer in China. Rare Earth Neodymium Magnet.

Dailymag is professional Rare Earth NdFeB Magnet manufacturer and exporter in China.

NdFeB magnets:

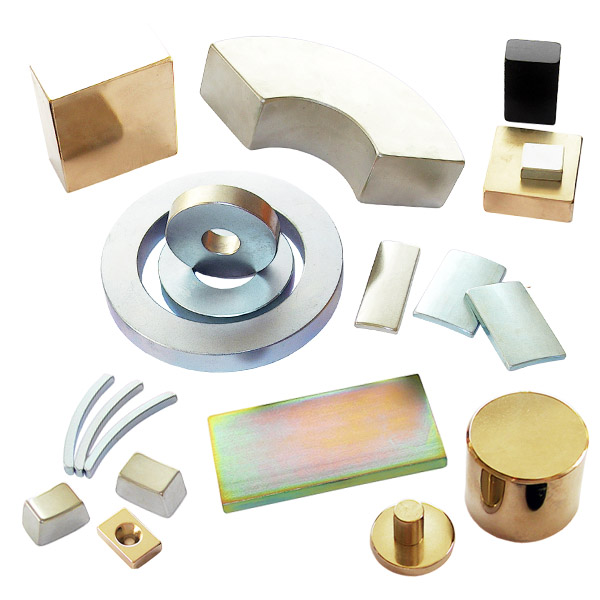

Neodymium magnets are also named NdFeB magnets because of their composition, i.e., neodymium (Nd) alloy, Iron (Fe), and Boron (B). These are the strongest permanent rare-earth magnets and are used widely. In 1984, general Motors and Sumitomo special metals manufactured neodymium (NdFeB) magnets for the first time. These magnets are available in diverse forms, i.e., circles, rings, cylinders, beads, blocks, slits, etc. NdFeB magnets are of great importance as they are used in modern technology, i.e., in hard disk, magnetic fasteners, automatic locks, cordless tools, medical diagnosis-based machines. Neodymium magnets are preferred over other types of magnets because of their low cost and efficient magnetic ability. We manufacture a range of different grading neodymium magnets in various shapes. Our NdFeB magnets are very reliable, user-friendly, and cost-effective.

NdFeB magnets for sale:

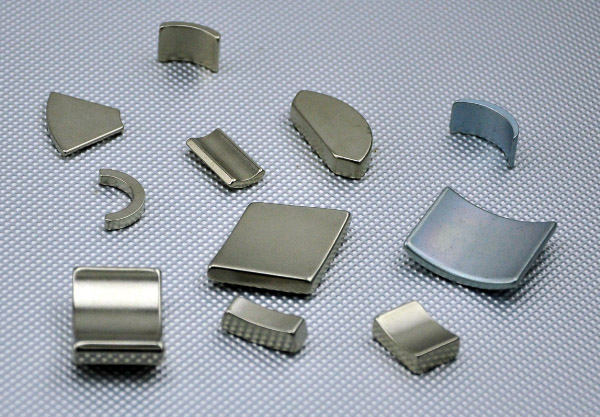

Neodymium (NdFeB) magnets of various grades and shapes are available for our customers. We provide our customers with high-quality and licensed interests in various required forms, i.e., disc, square, rectangular, beads, cylinder, trapezoid, and ring-shaped magnets. We can customize their sizes according to the specific requirements of the customers. Besides the mentioned ones, we can provide our facilities to manufacture any shape on customer's orders.

Basics of Neodymium magnet:

Neodymium magnets are permanent rare-earth magnets which has the highest strength of all the available permanent magnets. You can get them in a range of grades. The grade of a magnet is allotted respective to its composition, i.e., the high-grade magnet has a composition that enhances its magnetic strength compared to the lower grade magnets. A number usually indicates a grade after 'N,' such as N38 or N52. It is also followed by letters (M, H, SH, UH, EH), which stated the respective grade's temperature ratings. Neodymium magnets are also covered with nickel coatings to prevent corrosion of the brittle magnet. Neodymium magnets can resist demagnetization up to a certain temperature (80°C), after which it start losing its magnetization and completely lose it at 310°C. Although neodymium iron boron magnets have the strongest magnetic force in the world and have the largest energy product, exceeding the most powerful samarium cobalt magnets before, they are the only rare earth magnets that require surface coating. In order to avoid corrosion, they need to be protected on the surface. , Such as electroplating with nickel, zinc, tin, gold and spraying epoxy resin on the surface. (SmCo magnet, AlNiCo magnet, Ferrite magnet and Rubber magnet all the surface doesn't need to be protected, and it can be used directly after production and processing)

The NdFeB permanent magnet material is a permanent magnet material based on the intermetallic compound Nd2Fe14B. The main components are rare earth elements neodymium (Nd), iron (Fe), and boron (B). Among them, the rare earth element is mainly neodymium (Nd). In order to obtain different properties, some other rare earth metals such as dysprosium (Dy) and praseodymium (Pr) can be substituted. Iron can also be partially replaced by other metals such as cobalt (Co) and aluminum (Al). The content of boron is small, but it plays an important role in the formation of tetragonal crystal structure intermetallic compounds, making the compounds have high saturation magnetization, high uniaxial anisotropy and high Curie temperature.

The third-generation rare earth permanent magnet NdFeB is the most powerful permanent magnet in contemporary magnets. Its main raw material is rare earth metal neodymium 29%-32.5%, metallic element iron 63.95-68.65%, non-metallic element boron 1.1-1.2% and dysprosium 0.6-8% niobium 0.3-0.5% aluminum 0.3-0.5% copper 0.05-0.15% and other elements.

distinguish magnet

1. It is usually placed on a surface that can be adsorbed with a magnet of the same specification, such as: patch, blade, iron gate, etc., to distinguish the size of the magnetic force by hand

2. Use electronic scales: Magnets with weak magnetic force are generally related to their density. If the density is low, the magnetic force will be relatively small. If the weight is heavy, the magnetic force will be relatively large. On the contrary, if the weight is light, the magnetic force will be small. The test was done. [1]

Overview

Each type of product is divided into several grades according to the maximum magnetic energy product

The grades of NdFeB magnetic materials are: N35—N52, 35M—50M, 30H—48H, 30SH—45SH, 28UH—35UH, 28EH—35EH.

Grade example: 048021 means (BH) max is 366~398kj/m3, Hcj is 800KA/m sintered neodymium iron boron permanent magnet material.

The grade of sintered neodymium iron boron permanent magnet material consists of three parts: the main name and two magnetic properties. The first part is the main name, which is composed of the chemical symbol ND of neodymium element, the chemical symbol of iron element FE and the chemical symbol of boron element B. The second part is the number before the line, which is the nominal value of the material’s maximum magnetic energy product (BH) max (unit: kj/m3), and the third part is the number after the diagonal line, the coercive force value of the magnetic polarization (unit: One tenth of KA/m), the value is rounded up.

Brand example: NdFeb380/800 means (BH) max is 366~398kj/m3, Hcj is 800KA/MR sintered neodymium iron boron permanent magnet material.

Typical shape of NdFeB magnets:

|  |

| Block shape NdFeB Magnet | Disc shape NdFeB Magnet |

|  |

| Cylinader shape NdFeB Magnet | Ring shape NdFeB Magnet |

|  |

| Tile shape NdFeB Magnet | Customized shape NdFeB Magnet |

|  |

| Countersink hole on NdFeB Magnet | NdFeB Magnet with 3M adhesive |

|  |

| Sphere shape NdFeB Magnet | Rubber coated NdfeB Pot Magnet with screw thread |

NdFeB magnets technological process: ingredients → smelting ingot/spinning → powder making → profiling → sintering and tempering → magnetic inspection → grinding → pin cutting → electroplating → finished product. Among them, the ingredients are the foundation, and the sintering and tempering is the key.

NdFeB magnet blank production tools and performance testing tools: smelting furnace, belt spinning furnace, jaw breaking machine, jet mill, compression molding machine, vacuum packaging machine, isostatic press, sintering furnace, heat treatment vacuum furnace, magnetic performance test Meter, Gauss meter.

NdFeB magnet machining tools: centerless grinding, spheronization machine, double-end grinding, flat grinding, slicer, double-sided grinding, wire cutting, bench drill, special-shaped grinding, etc.

General characteristics of NdFeB magnets:

We manufacture our neodymium magnets according to the standard requirements. Our product contains the following essential characteristics:

• NdFeB has high saturation magnetization, which enables them to resist demagnetization.

• Flux density of NdFeB varies very slowly, so neodymium magnets remain stable for a longer duration.

• The magnetic strength of the neodymium magnet is far more than the ordinary magnets.

• The factors such as high temperature and constant charged field can affect the magnetization ability and flux density of neodymium magnets.

• NdFeB magnets are usually brittle but can resist chip or crack up to a certain external force limit.

• Neodymium magnets are less expensive as compare to other rare-earth metals.

• NdFeB magnets of all the possible grade ranges are available for our customers.

• Neodymium magnets have less Curie temperature.

• The crystals of magnet are arranged in micro-grains to keep the direction of magnetization on one axis.

• These magnets have a tendency of corrosion under high moisture content and hence, required to be covered by protective coverings.

Our highly experienced engineer staff and modern manufacturing units enable us to manufacture high-quality neodymium magnets. Still, sometimes customers demand some different types of products for their applications. We try our best to meet the requirements of our customers.

Selection of NdFeB magnet:

The selection of a magnet suitable for the required task or application is the most critical point for customers because magents of different grades or sizes are ideal for specific applications. For example, if a NdFeB magnet has to be used as a sensor magnet, the requirement is to produce a particular magnetic field in a small range. For this, tiny magnets of low grade are enough instead of N52, which may cause incorrect readings. Similarly, if a NdFeB magnet has to be adopted in motors, N48 is preferred over higher grade, I.e., N55, which may overheat in that condition.

Considerations for selection:

We always try our best to help our customers find the best suitable magnet according to the condition where they want to use the magnet. There are some aspects that we recommend our customers consider while selecting the NdFeB magnet for their application:

• Temperature of the working site of the magnet.

• Any other metal (silver, platinum) or other material (plastic) is supposed to be present next to the magnet.

• The area of the site where magnet is to be placed for work.

• Requirement of any extra protective coating of metal around the metal.

• Tolerance requirement

• The presence of magnet, i.e., in assembled firm or individual.

• Required shape and size of the magnet in accordance to the working place.

Pricing strategy:

Pricing of our products also follows the general rule according to which higher the grade higher the rates, i.e., N48SH costs more than N48H, which is relatively expensive than a low-grade N48 NdFeB magnet. These letters indicate the grading of magnets. It should also be noted that a low-grade material with a higher letter (N35SH) also costs more than high-grade material with no letter (N38). We can vary this pricing depending upon the relative size and shape of the required grade magnet.

Applications:

The high magnetic strength of neodymium magnets makes them very efficient options to be used at the industrial and commercial level. These are used in wind turbines, hybrid vehicles, mounting tools, clamps, levitation devices, and geocaching. Neodymium magnets are also used in medical devices such as MRI scanners. Recently, NdFeB magnets are also used as jewelry clamps, headphones, speakers, locks, and children's toys. Moreover, NdFeB magnets are also used electric motors, spectrometers, voice coils, compressors and loud speakers. These magnets are used inanti-reflux system in which magnet bar is placed inside the body.

Precautions:

The handler should use NdFeB magnets with care to prevent any harm. These magnets should not be employed at high temperatures. Conventional methods should not machine neodymium magnets because it can cause heating, leading to either the demagnetization of the or may cause burning, which produces toxic gases. NdFeB magnets have a strong magnetic field; therefore, prolonged exposure to them is not appreciated. These magnets are brittle in nature and can crack or break upon extreme force.