Item No.: smco

Sintered SmCo Magnet

Sintered SmCo Magnet (Powerful magnets, permanent magnet).

General Introduction

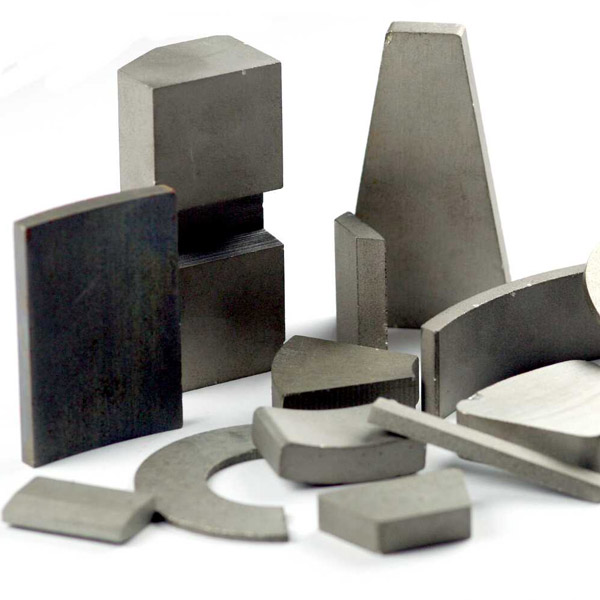

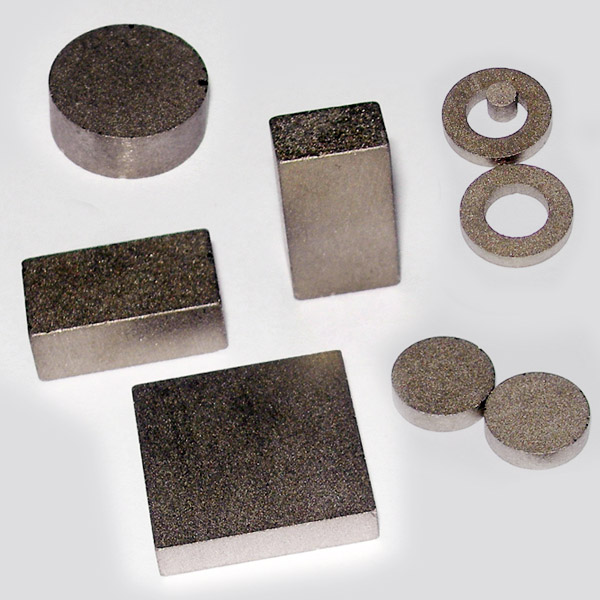

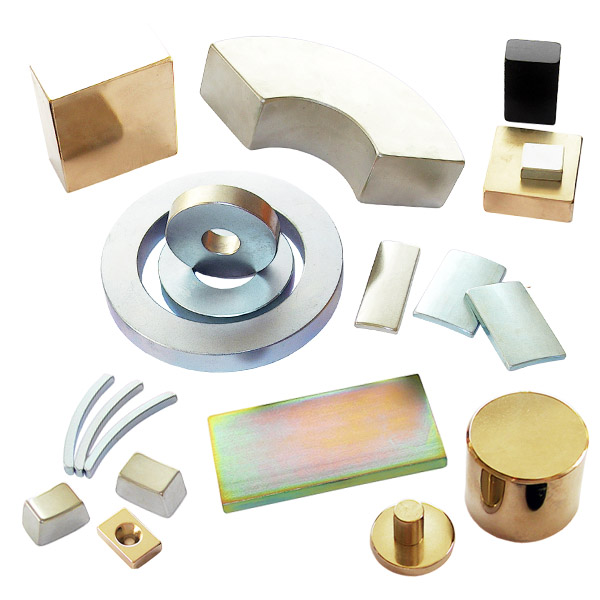

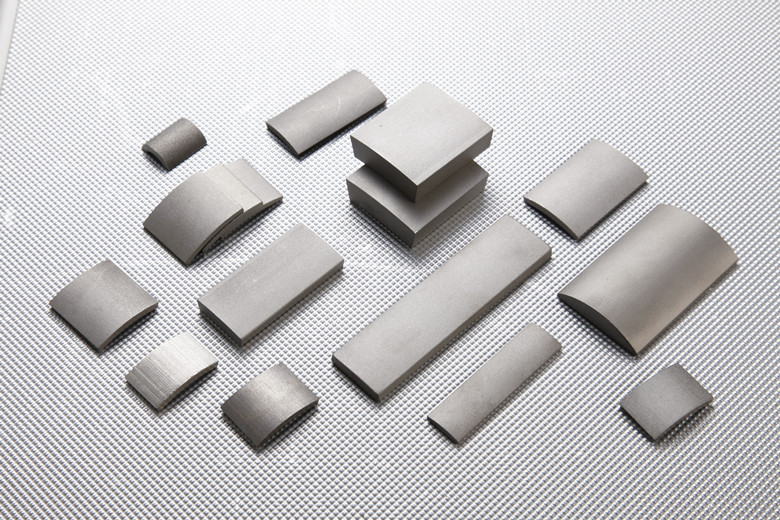

Sintered SmCo Magnet (SmCo magnets, magnetic rings, magnetic tiles, block magnets, magnetic cylinder, rare earth magnets, disc magnets,strong magnets, powerful magnets, permanent magnet).

Sintered SmCo Magnet (SmCo Magnets) is biggest advantage is its high working temperature -350℃,in general ,magnetizing field of approximately 30 to 45 KOe are required. SmCo magnet is widely used in motors, meters, transducers, instruments, positional detector, generators , wind power generators, radar and other applications.

We are professional Manufacturer of Sintered SmCo Magnet and SmCo Magnets in china.

What shapes can it be formed with Sintered SmCo magnet? Sintered SmCo Magnet

|  |

|  |

Magnetic properties of SmCo5 (Sintered SmCo Magnet)

| Material | Grade | Remanence | Coercive Force | Intrinsic Coercive Force | Max. energy product | Curie Temperature | Max. Operating Temperature | Temperature Coefficient of Br | Temperature Coefficient of Hc | ||||

| Br | Hcb | Hcj | (BH)max | Tc | Tw | ||||||||

| SmCo5 (Smpr)co5 | T | KGs | KA/m | KOe | KA/m | KOe | KJ/m3 | MGoe | °C | °C | %°C | %°C | |

| YX- 16 | 0.81-0.85 | 8.1- 8.5 | 620-660 | 7.8- 8.3 | 1194-1830 | 15-23 | 110-127 | 14-16 | 750 | 250 | -0.05 | -0.3 | |

| YX- 18 | 0.85-0.9 | 8.5- 9.0 | 660-700 | 8.3- 8.8 | 1194-1830 | 15-23 | 127-143 | 16-18 | 750 | 250 | -0.05 | -0.3 | |

| YX- 20 | 0.9-0.94 | 9.0- 9.4 | 680-725 | 8.5-9.1 | 1194-1830 | 15-23 | 150-167 | 19-21 | 750 | 250 | -0.05 | -0.3 | |

| YX- 22 | 0.92-0.96 | 9.2- 9.6 | 710-750 | 8.9-9.4 | 1194-1830 | 15-23 | 160-175 | 20-22 | 750 | 250 | -0.05 | -0.3 | |

| YX- 24 | 0.96-1.0 | 9.6- 10.0 | 730-770 | 9.2-9.7 | 1194-1830 | 15-23 | 175-190 | 22-24 | 750 | 250 | -0.05 | -0.3 | |

| SmCo5 | YX- 20s | 0.9-0.94 | 9.0- 9.4 | 680-725 | 8.5-9.1 | 1433-1830 | 18-23 | 143-160 | 18-20 | 750 | 250 | -0.05 | -0.3 |

| YX- 22s | 0.92-0.96 | 9.2- 9.6 | 710-750 | 8.9-9.4 | 1433-1830 | 18-23 | 160-175 | 20-22 | 750 | 250 | -0.05 | -0.3 | |

| Low temperature coefficient SmCo5 (SmGd)Co5 | LTc (YX- 10) | 0.59-0.63 | 5.9- 6.3 | 460-493 | 5.8-6.2 | 1430-1830 | 18-23 | 68-80 | 8.5-10 | 700 | 250 | Temperature | Temperature Coefficient of Br %°C |

| 20-100°C | -0.004 | ||||||||||||

| 100-200°C | -0.021 | ||||||||||||

| 200-300°C | -0.042 | ||||||||||||

| ce(coFecu)5 | YX- 12 | 0.70-0.74 | 7.0- 7.4 | 358-390 | 4.5-4.9 | 358-478 | 4.5-6 | 80-103 | 10-13 | 450 | 200 | ||

Magnetic properties of Sm2Co17 (Sintered SmCo Magnet)

| Material | Grade | Remanence | Coercive Force | Intrinsic Coercive Force | Max. energy product | Curie Temperature | Max. Operating Temperature | Temperature Coefficient of Br | Temperature Coefficient of Hc | ||||

| Br | Hcb | Hcj | (BH)max | Tc | Tw | ||||||||

| Sm2Co17 Sm2 (CoFecuzr)17 | YXG- 24H | 0.95-1.02 | 9.5- 10.2 | 700-750 | 8.7-9.4 | =1990 | =25 | 175-191 | 22-24 | 800 | 350 | -0.03 | -0.2 |

| YXG- 26H | 1.02-1.05 | 10.2- 10.5 | 750-780 | 9.4-9.8 | =1990 | =25 | 191-207 | 24-26 | 800 | 350 | -0.03 | -0.2 | |

| YXG- 28H | 1.03-1.08 | 10.3- 10.8 | 756-796 | 9.5-10 | =1990 | =25 | 207-220 | 26-28 | 800 | 350 | -0.03 | -0.2 | |

| YXG- 30H | 1.08-1.10 | 10.8- 11.0 | 788-835 | 9.9-10.5 | =1990 | =25 | 220-240 | 28-30 | 800 | 350 | -0.03 | -0.2 | |

| YXG- 24 | 0.95-1.02 | 9.5- 10.2 | 700-750 | 8.7-9.4 | =1433 | =18 | 175-191 | 22-24 | 800 | 300 | -0.03 | -0.2 | |

| YXG- 26 | 1.02-1.05 | 10.2- 10.5 | 750-780 | 9.4-9.8 | =1433 | =18 | 191-207 | 24-26 | 800 | 300 | -0.03 | -0.2 | |

| YXG- 28 | 1.03-1.08 | 10.3- 10.8 | 756-796 | 9.5-10 | =1433 | =18 | 207-220 | 26-28 | 800 | 300 | -0.03 | -0.2 | |

| YXG- 30 | 1.08-1.10 | 10.8- 11.0 | 788-835 | 9.9-10.5 | =1433 | =18 | 220-240 | 28-30 | 800 | 300 | -0.03 | -0.2 | |

| YXG- 26M | 1.02-1.05 | 10.2- 10.5 | 750-780 | 9.4-9.8 | 955-1273 | 12-16 | 191-207 | 24-26 | 800 | 300 | -0.03 | -0.2 | |

| YXG- 28M | 1.03-1.08 | 10.3- 10.8 | 756-796 | 9.5-10.0 | 955-1273 | 12-16 | 207-220 | 26-28 | 800 | 300 | -0.03 | -0.2 | |

| YXG- 30M | 1.08-1.10 | 10.8- 11.0 | 788-835 | 9.9-10.5 | 955-1273 | 12-16 | 220-240 | 28-30 | 800 | 300 | -0.03 | -0.2 | |

| YXG- 28L | 1.02-1.08 | 10.2- 10.8 | 398-445 | 5.0-5.6 | 400-520 | 5.2-6.5 | 207-220 | 26-28 | 800 | 250 | -0.03 | -0.2 | |

| YXG- 30L | 1.08-1.15 | 10.8- 11.5 | 398-445 | 5.0-5.6 | 400-520 | 5.2-6.5 | 220-240 | 28-30 | 800 | 250 | -0.03 | -0.2 | |

| Low temperature coefficient Sm2Co17 (SmEr)2 (CoTM)17 | LTC (YXG- 22) | 0.94-0.98 | 9.4- 9.8 | 668-715 | 8.4-9.0 | 1194-1591 | 15-20 | 167-183 | 21-23 | 840 | 300 | Temperature | Temperature Coefficient of Br %°C |

| -50-25°C | +0.005 | ||||||||||||

| 20-100°C | +0.012 | ||||||||||||

| 100-200°C | +0.006 | ||||||||||||

| 200-300°C | -0.025 | ||||||||||||

Characteristic comparisons of permanent magnetic materials:

| Materials | (BH)max | Hcj | Br Tc | (Working temperature)max | Anti-causticity |

| SmCo1:5 | 16-25 | 15-25 | -0.05 | 200-250 | Good |

| SmCo2:17 | 22-30 | 6-30 | -0.03 | 300-350 | Good |

| NdFeB | 26-52 | 12-30 | -0.11 | 80-200 | Bad |

| Ferrite magnet | 3-4.5 | 3-4.5 | -0.19 | 200-300 | Good |

| AINiCo | 5-10 | 1-1.8 | -0.03 | 450-500 | Excellent |

Process Flow:

Raw material-----Mixing-----Melting-----Power-----Pressing-----Sintering----Magnetic Inspection-----Cutting and Grinding-----Inspection-----Packing and Shipping

Sintered SmCo Magnet, SmCo Permanent Magnet, Magnetic Material for you now