How are sintered NdFeB permanent magnets produced?

Sintered NdFeB permanent magnets are produced by powder metallurgy. Generally, there are more than a dozen process links from material preparation to finished product delivery, and several testing and analysis are also included in different stages.

The whole production process is a systematic project, which is closely linked. Generally, the process of producing magnet blanks is called the front-end production process, and the process of processing the blanks into final products is called the post-process process. Magnetic material manufacturers are mainly divided into two categories, one is a manufacturer that has both front-end production and post-processing, and the other is a processing manufacturer that focuses on post-processing.

1. Preparation

There is a saying that "the medicine is good, the medicine is good", this sentence is very suitable for the production of sintered NdFeB magnets. Good raw materials are the basis for the production of high-quality magnetic materials. When manufacturers choose rare earth praseodymium neodymium metal raw materials, they generally choose according to the performance requirements of magnets and the corresponding national standards. The raw material is cut and surface treated before smelting.

2. Smelting

Smelting is the first process of sintering NdFeB permanent magnets into the production process. The raw materials are heated and smelted in the smelting furnace and cooled to form alloy strips. This process requires the furnace temperature to reach about 1300 degrees and lasts for more than four hours to complete.

3. Hydrogen breaking and 4. Jet mill

The two process links of hydrogen crushing and jet milling are collectively referred to as pulverizing, which is the process of crushing the smelted alloy strip and making magnetic powder. In order to obtain well-oriented magnets, it is required that the powder particle size is small (3-4 μm) and the size distribution is concentrated, and the powder particles are spherical or nearly spherical.

5. Pressing

The crushed magnetic powder is loaded into a mold, an external magnetic field is applied for orientation, and the powder is pressed after orientation. Powder magnetic field orientation is one of the key process technologies for producing high-performance sintered NdFeB. In the molding process, there are currently three methods commonly used in the industry: molding method, molding plus cold isostatic pressing and rubber mold isostatic pressing. Under the same neodymium content, rubber mold isostatic pressing can obtain greater magnetic energy. product.

6. Heat treatment

After pressing, the relative density of the magnet compact is relatively large. In order to make the magnet have high permanent magnet performance, the compact needs to be heated to a temperature below the melting point of the basic phase of the powder, and heat treated for a period of time. This process is also called sintering. After high temperature quenching, it is necessary to perform tempering treatment at a certain temperature to optimize the microstructure and obtain the best magnetic properties. (Tempering refers to cooling the sintered magnetic powder blank to a certain temperature and heating it up again)

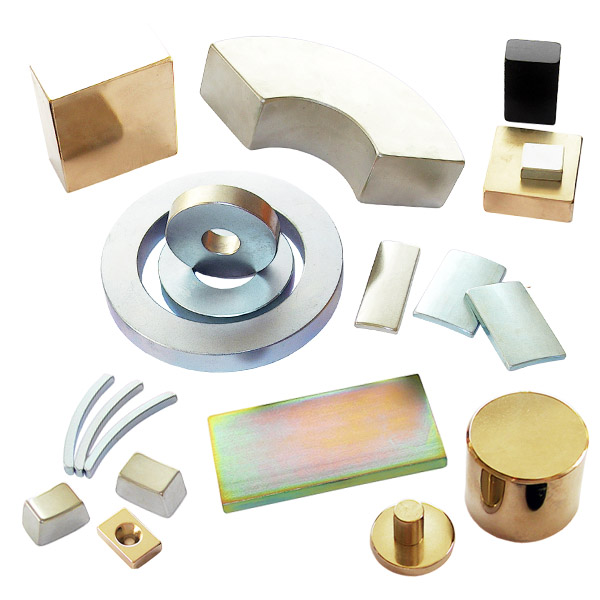

7. Machining

Due to the characteristics and technical limitations of the magnetic field orientation forming process, it is difficult for sintered magnets to directly achieve the shape and dimensional accuracy of practical applications. Sintered NdFeB material is hard and brittle, and general machining can only be performed by cutting, drilling, grinding and rolling.

Japanese and European and American companies mostly choose near-net forming process due to consideration of raw material and labor costs, supplemented by follow-up machining; Chinese companies produce a wide range of sintered NdFeB products, mainly using the comprehensive production process of combined blank magnets and post-processing, and fully learn from The technological advantages of ceramic and crystal processing bring the mechanical processing level of rare earth permanent magnets to the extreme. With the increase of raw material cost and labor cost pressure, near-net-shape forming and automatic forming technology are developing rapidly in our country.

8. Grain boundary diffusion

The rare earth elements dysprosium and terbium can greatly improve the coercivity and temperature stability of the material. For sintered NdFeB materials with high coercivity and operating temperature requirements, dysprosium and terbium are often added, but the price of these two elements Very high, the production cost of magnets will increase sharply. At present, grain boundary diffusion technology is generally used in the industry to reduce the amount of heavy rare earth elements added.

9. Surface treatment

Sintered NdFeB is a powder material with very strong chemical activity. There are tiny pores and voids inside, which are easily corroded and oxidized in the air. Over time, the magnetic properties will be attenuated or even lost. Therefore, strict surface inspection must be carried out before use. Anti-corrosion treatment. At present, NdFeB anti-corrosion treatment generally adopts electroplating, chemical plating, electrophoresis, phosphating and other methods, among which electroplating is widely used as a mature metal surface treatment method.

10. Magnetization

Magnetization is a key step for sintered NdFeB permanent magnets to obtain magnetism. A magnetizer is a tool for magnetizing magnetic materials or magnetic devices, through which a magnetic field is applied to the magnetized NdFeB magnets. If the magnetized magnetic field cannot reach the technical saturation magnetic field, the remanence Br and the coercive force Hcj of the permanent magnet cannot reach their due values. In addition to ordinary single-pole magnetization, sintered NdFeB can also perform multi-pole magnetization according to actual needs, that is, multiple N and S poles can appear on a plane after magnetization.

11. Quality inspection, packaging and delivery

Quality Inspection

The quality monitoring in the production process of sintered NdFeB permanent magnets and the quality inspection of the final product should include the items listed in the table below, but not every item needs to be inspected. The purchaser can negotiate the required inspection with the manufacturer according to actual needs. project.

Packaging and delivery is the last link before the magnet leaves the factory. The magnet manufacturer can package according to the buyer's requirements. If the buyer has special packaging requirements, they can explain to the supplier in advance. Sintered NdFeB permanent magnets have strong magnetic properties, so domestic transportation generally uses land transportation. Those exported overseas can be shipped by air after special magnetic isolation packaging and inspection and appraisal by professional institutions.