How to determine Magnets in permanent magnet motors?

The largest application field of rare earth permanent magnets is permanent magnet motors. Motors are commonly known as motors. In a broad sense, motors include motors that convert electrical energy into mechanical energy, and generators that convert mechanical energy into electrical energy. Both motors and generators are used. Electrical equipment with the law of electromagnetic induction or the law of electromagnetic force as the underlying principle. The air-gap magnetic field is the premise of the working principle of the motor. The air-gap magnetic field generated by electric excitation is called an induction motor, and the one generated by a permanent magnet is called a permanent magnet motor.

The air-gap magnetic field in the permanent magnet motor is generated by the permanent magnet, which does not require additional electric energy or additional windings. Therefore, the biggest advantage of the permanent magnet motor compared with the induction motor is high efficiency, energy saving, small size, and simple structure, so the permanent magnet motor The application of magneto, especially in all kinds of small and micro motors, is widely used.

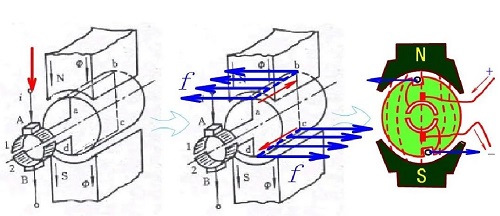

The figure below is a simple model of the working principle of a permanent magnet DC motor. Two permanent magnets generate a magnetic field at the coil in the center, and the coil is passed a current. The electromagnetic force (left-hand rule) will be generated under the action of the magnetic field, and then rotate. The motor The rotating part is called the rotor, and the stationary part is called the stator. Obviously, the permanent magnet in the figure below belongs to the stator, and the coil belongs to the rotor.

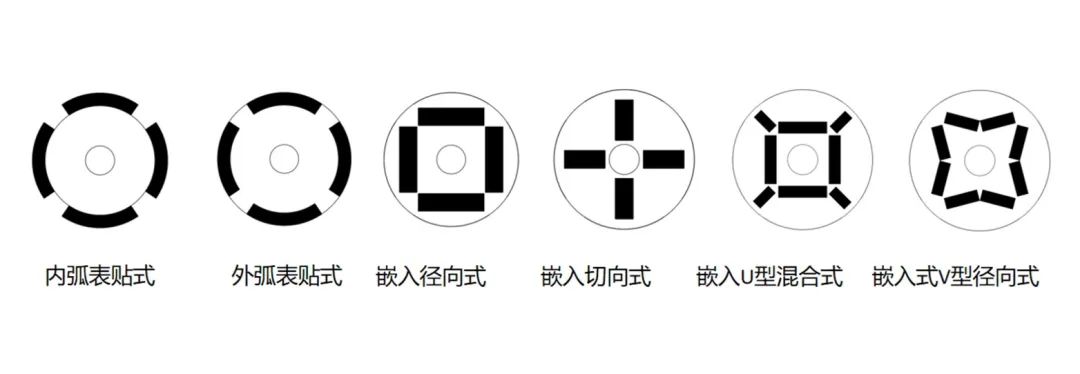

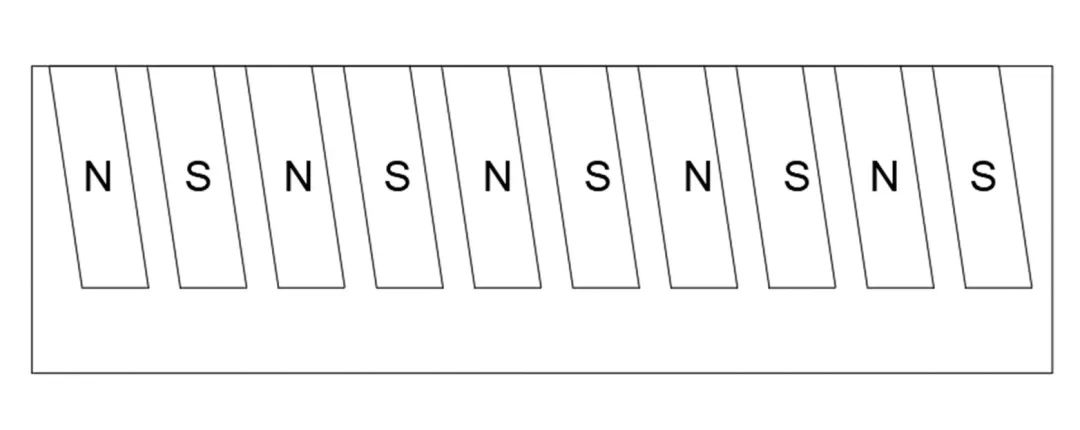

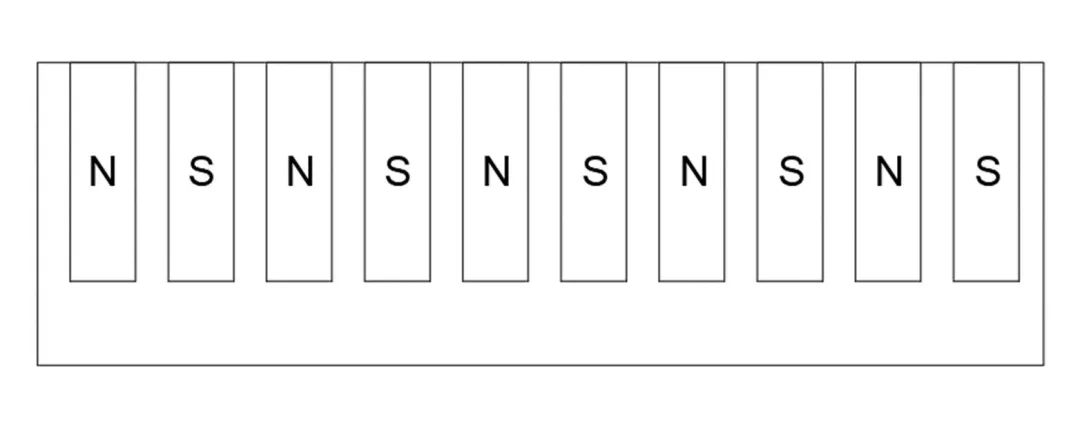

For rotating electrical machines, when the permanent magnet is the stator, the outer arc surface-mounted tile-shaped magnet is attached to the casing; when the permanent magnet is the rotor, the inner arc surface-mounted tile-shaped magnet is attached to the rotor core. , or embedded in the rotor core in a square shape, as shown in the figure below.

For linear motors, the permanent magnets are mainly square and parallelogram, and cylindrical linear motors also use axially magnetized ring magnets.

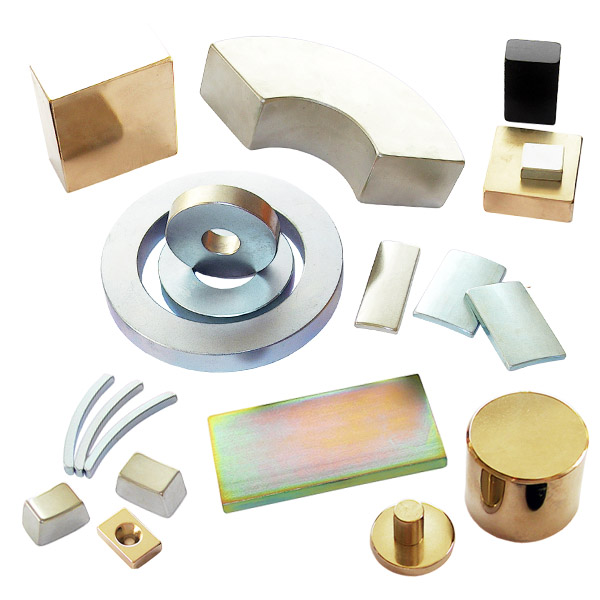

Permanent magnet motor magnets have the following characteristics:

1. The shape will not be too complicated (except for some micro motors, such as VCM motors), most of which are rectangular, tile-shaped, fan-shaped, and bread-shaped. Especially under the premise of reducing the cost of motor design, many of them will use embedded square magnets steel;

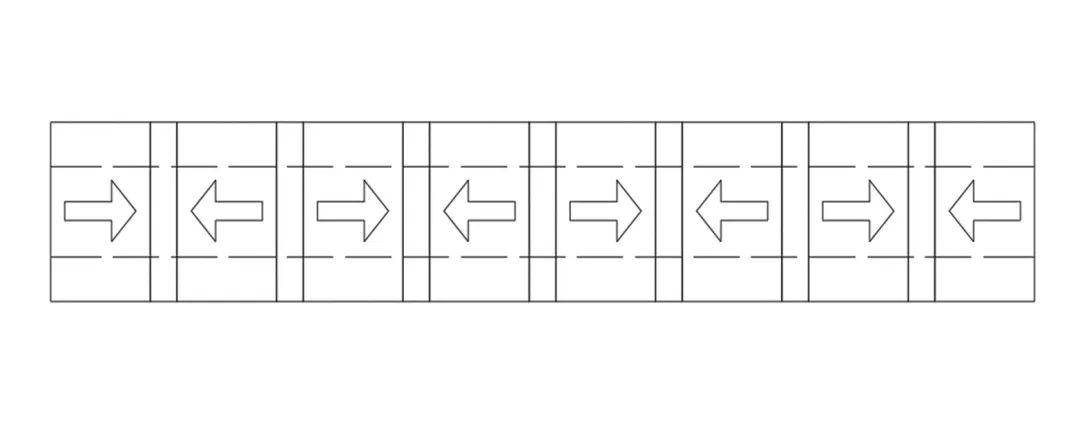

2. Magnetization is relatively simple, basically unipolar magnetization, and a multi-pole magnetic circuit is formed after assembly. If the whole ring is made, such as bonding NdFeB magnetic ring or hot-pressed magnetic ring, multi-pole radiation magnetization is generally used;

3. The core of technical requirements mainly lies in high temperature stability, magnetic flux consistency and adaptability. Surface-mounted rotor magnets will require good affinity for glue. Linear motor magnets will have relatively strict requirements for salt spray. Wind power magnets The requirements for salt spray will be stricter, and the drive motor magnet will require very good high temperature stability;

4. The magnetic energy product is applied in high, medium and low grades, but the coercive force is mostly at the medium and high-end level. At present, the magnetic steel grades of the drive motors of electric vehicles are mostly high magnetic energy product and high coercive force, such as 45UH, 48UH, 50UH, 42EH , 45EH, etc. Mature diffusion process is essential;

5. Segmented bonding magnets have been widely used in the field of high-temperature motors. The purpose is to improve the segmental insulation of the magnets to reduce the eddy current loss of the magnets when the motor is running, and some magnets will be on the surface. Epoxy coating is added to increase its insulation.

Key testing items for motor magnets:

1. High temperature stability. Some customers will request to measure the magnetic decay of open circuit, and some customers will request to measure the magnetic decay of semi-open circuit. When the motor is running, the magnetic steel must bear the alternating reverse magnetic field in addition to high temperature, so the magnetic decay of the finished product and the high temperature demagnetization curve of the base material must be tested and monitored;

2. Flux consistency. Magnetic steel is used as the magnetic field source of the motor rotor or stator. If there is a difference in consistency, it will cause vibration of the motor, reduce power and affect the function of the overall motor. Therefore, the magnetic steel of the motor generally has requirements for the consistency of the magnetic flux, and some require 5% Within, some require within 3% or even 2%. Factors that affect the consistency of magnetic flux must be taken into account, such as the consistency of residual magnetism, the consistency of tolerances, and the consistency of chamfering coatings.

3. Adaptability. Most of the surface-mounted magnets are tile-shaped. For the included angle and radian, the conventional two-dimensional test method has large errors or is difficult to test. At this time, its adaptability needs to be considered. Some closely arranged magnets require To control the accumulative gap, some dovetail surface-mounted magnetic steel needs to consider the tightness of assembly. It is best to make a profiling fixture according to the user's assembly method to test the suitability of the magnetic steel.

Purchasing personnel need to focus on the following points:

1. Rare earth market. As the single item cost of the motor accounts for the largest part, the magnet steel has always been the main source of motor cost reduction. Because the shape of the motor magnet itself is relatively simple, the material cost accounts for the largest proportion. Purchasers need to pay attention to rare earth metals at any time. Market conditions, in order to understand the price trend of motor magnets;

2. Performance indicators. The shape of the magnetic steel is relatively simple, and the material cost accounts for a large proportion, so the performance index will directly affect the amount of heavy rare earth in the magnetic steel, thereby directly affecting the cost of the magnetic steel;

3. Quantity. Most of the motor magnets are relatively large, with a length as small as 10mm and as large as more than 100mm. The number of pieces produced from a blank will not be many, so when the demand is not large, there will be a large waste of blanks in stock, and the production of fixed molds will require The problem of apportioning mold costs results in higher costs.