Orientation and magnetization of sintered NdFeB magnets

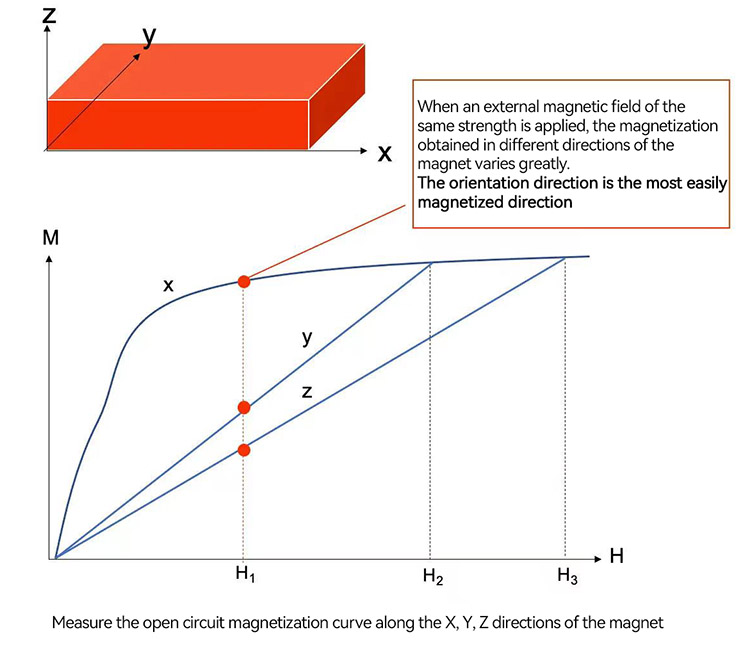

Magnetic materials are divided into two categories: isotropic magnets and anisotropic magnets:

1. The magnetic properties of isotropic magnets are the same in any direction, and can be magnetized arbitrarily;

2. Anisotropic magnets have different magnetic properties in different directions, and the direction in which the best magnetic properties can be obtained is called the orientation direction of the magnet.

Common anisotropic magnets are mainly hard magnetic materials such as sintered NdFeB and sintered SmCo. Anisotropic magnet:

Orientation is an important process link in the production of sintered NdFeB magnets.

The magnetism of the magnet comes from the magnetic order (arranging the magnetic domains in one direction), and the sintered NdFeB is formed by pressing the magnetic powder in the mold. Put the magnetic powder into a mold to give a given shape, apply a strong magnetic field through the electromagnet, and at the same time give a certain pressure to the magnetic powder by the press, so that the easy magnetization axis of the magnetic powder is aligned. After pressing, the blank is demagnetized, and then demolded to obtain a blank with a good orientation in the direction of easy magnetization, which is then cut into a finished magnetic steel product of a specified size according to the user's needs.

Powder orientation is the key process for preparing high-performance NdFeB permanent magnets. Whether the magnet orientation is good in the blank production stage is affected by many factors, including: orientation magnetic field strength, powder particle shape and size, molding method, orientation field and molding pressure. Direction, bulk density of oriented powder, etc.

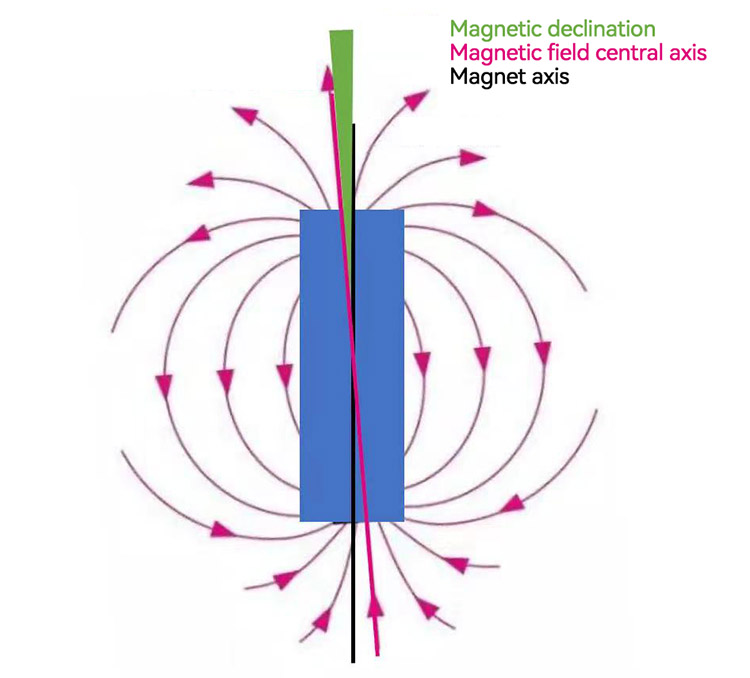

The magnetic declination angle generated in the post-processing link has a certain influence on the magnetic field distribution of the magnet.

Magnetic declination refers to the angle between the direction of the magnet's magnetic force line and the magnet's orientation plane. The ideal state of the magnetic declination is perpendicular to the orientation plane, but in the post-processing process, due to the operation of the adhesive and the cutting process, there will be a certain angle between the cutting direction and the polar plane. After the subsequent magnetization, The magnetic field strength of the orientation plane will be lower than the normal magnetic field strength.

Magnetic declination:

Magnetization is the last step for sintered NdFeB to obtain magnetism.

The magnet blank is cut to obtain the size required by the user, and then undergoes anti-corrosion treatment such as electroplating to become a finished magnet steel. However, at this time, the magnet itself does not show magnetism to the outside, and it is necessary to go through the process of magnetization to "magnetize" the magnet.

The equipment we use to magnetize the magnetic steel is a magnetizer, also called a magnetizer. The magnetizer first charges the capacitor with a DC high-voltage voltage (that is, energy storage), and then discharges it through a coil with a very small resistance (magnetizing fixture). The peak value of the discharge pulse current is very high, up to tens of thousands of amperes. This current pulse creates a strong magnetic field within the magnetizing fixture, which permanently magnetizes the magnets placed in the magnetizing fixture.

Accidents also occur during the magnetization process, such as unsaturated magnetization, bursting of the pole head of the magnetizer, broken magnets, etc.

*Magnetization is not saturated mainly because the magnetization voltage is not enough, and the magnetic field generated by the coil cannot reach 1.5~2 times of the saturation magnetization of the magnet.

*If it is multi-pole magnetization, it is difficult to magnetize magnets with relatively thick orientation directions to saturation, because the distance between the upper and lower poles of the magnetizer is too large, and the magnetic field strength generated by the poles is not enough to form a normal magnetizer. The closed magnetic circuit of the magnet cannot penetrate the magnet through the magnetic field, so it will cause the magnetic poles to be confused and the magnetic field strength is not enough.

*The bursting of the magnetizing pole is mainly because the set voltage is too high, exceeding the safe voltage of the magnetizer.

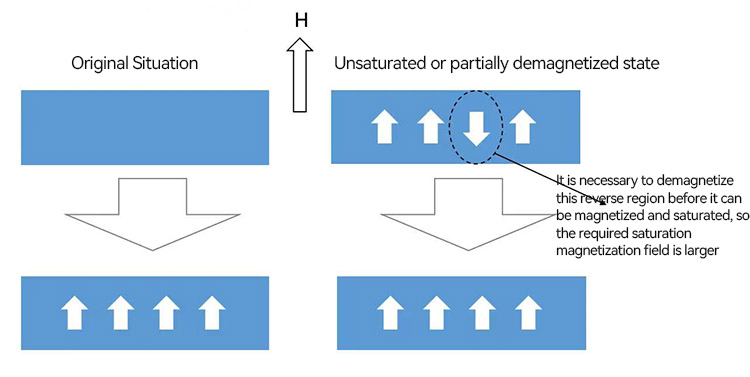

Unsaturated magnets or magnets that have been demagnetized will be more difficult to fill and saturate, because the magnetic domains in the original state are chaotic and do not show magnetism to the outside. To fill and saturate, you only need to overcome the resistance of the displacement and rotation of the magnetic domains themselves. . However, when the magnet is not fully charged, or demagnetized but not fully demagnetized, there is a reverse magnetic field area inside it. Whether it is forward magnetized or reverse magnetized, there are parts of the magnetized area that need to be reversed, and additional magnetization is required. To overcome the intrinsic coercive force in the reverse magnetic field region, a stronger magnetic field than the theoretical magnetizing magnetic field is required.

Uncharged or partially demagnetized magnets require a larger saturation magnetization field:

It is necessary to demagnetize this reverse region before it can be magnetized and saturated, so the required saturation magnetization field is larger.