Production process of sintered NdFeB magnet -(4) sintering, heat treatment and machining

publish_time:June 19, 2021, 3:44 p.m.Sintering and heat treatment

The magnetic field-oriented compacted blank is sintered under high vacuum or pure inert atmosphere to reach a high density close to 95% of the theoretical density. The magnet hole is a closed structure to ensure the uniformity of the magnetic flux density. The chemical stability of the metal; and because of the magnet’s The properties of permanent magnets are closely related to their metallic microstructures. The heat treatment process after sintering is very important for the adjustment of magnetic properties. However, after all, the treatment temperature is low. Some important microstructure characteristics cannot be adjusted by heat treatment, but must be adjusted by heat treatment. Carefully control the sintering process.

In order to avoid the decrease in coercivity caused by the growth of the main phase grains as much as possible, Nd-Fe-B magnets need to be sintered at a temperature lower than 1100°C, the usual sintering temperature is 1050~1080°C, and close to zero porosity can be obtained. In order to obtain high coercivity, two-stage heat treatment at around 900℃ and around 500℃ is usually required, and quenching is required to fix the corresponding microscopy after sintering and heat treatment. structure. The best heat treatment temperature and time combination is closely related to the added elements and their composition in the Nd-Fe-B magnet, but a large number of experiments show that the first-stage heat treatment temperature (900℃) has a wide range of universality, because the temperature is rich The Nd phase is in a liquid state. As a grain boundary phase, it can repair the surface of the main phase grains. As long as the time is not too long, it will not cause the main phase grains to grow excessively or enrich the Nd-rich phase. This effect is not related to the composition. The second-stage heat treatment is very important for the adjustment of the phase composition and microstructure of the magnet. Eutectic reaction will occur in this temperature zone, and the total amount, composition and distribution of the liquid phase will change, so it will be sensitive It affects the intrinsic coercivity of the magnet, the squareness of the demagnetization curve and the irreversible loss of the magnet at high temperature.

Machining

Due to the characteristics and technical limitations of the magnetic field orientation forming process, it is difficult for sintered magnets to directly achieve the shape and dimensional accuracy of practical applications at one time, so the mechanical processing of sintered blanks is inevitable. The main reasons are:

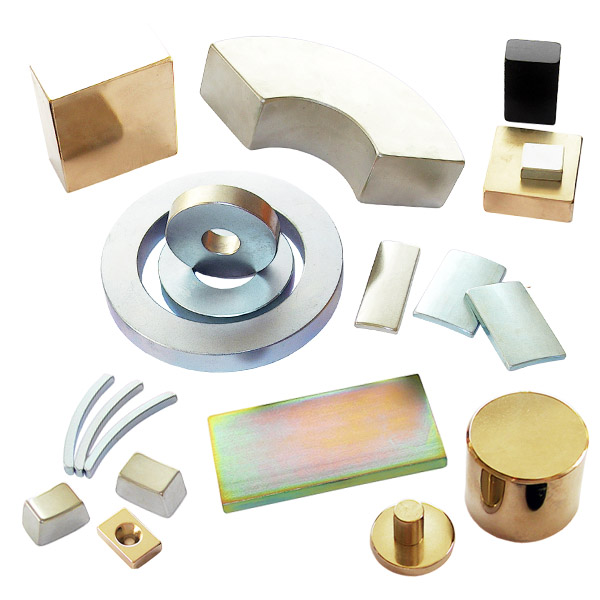

1. Many finished magnets are small in size and complex in shape, and can only be processed by a certain shape of the blank magnet;

2. Even for the near-finally formed blank magnets, due to the low powder density and poor fluidity, the female mold filling uniformity is poor, and it is difficult to avoid fluctuations in the shape or size of the sintered magnet blank;

3. Due to the obvious difference in sintering shrinkage between the parallel and perpendicular to the orientation direction of the Nd-Fe-B blank magnet, and the difference in sintering shrinkage between the border and the center of the blank magnet, it is difficult to meet the dimensional accuracy requirements of the finished magnet.

Japanese, European and American companies mostly choose the near-final forming process due to the consideration of raw material and labor costs, supplemented by subsequent mechanical processing; Chinese companies produce a wide range of rare earth permanent magnet products, mainly using a comprehensive production process that combines rough magnets with post-processing, and makes full use of ceramics. And the technological advantages of crystal processing have brought the machining level of rare earth permanent magnets to the extreme. With the increase of raw material cost and labor cost pressure, near-final forming and automatic forming technology are developing rapidly in our country.

The rare earth permanent magnet prepared by powder metallurgy is a typical cermet product. It is hard and brittle. For hard and brittle materials, the only tools used for machining are cutting, drilling, and drilling. Grinding and barreling. It can be subdivided according to the basic characteristics of the machined surface:

Blade cutting usually uses diamond or cubic boron nitride powder electroplated blades. Different blade thicknesses and blade edge positions are selected according to the incision depth and geometric tolerance requirements. The edge of the inner cutter is supported by the blade and the outer ring. The cutting process can ensure good flatness, so the thickness of the blade can be 0.1mm, but the depth of the cut and the size of the cut magnet are limited by the difference between the inner diameter and the inner and outer diameter of the blade. The cutting edge of the outer circular cutter floats on the outer edge, and the supporting capacity of the blade is inferior to that of the inner circular cutter. Therefore, a slightly thicker blade is required to ensure the same tolerance level, generally in the range of 0.2~0.5mm, and the resulting material loss is also Bigger. For products with large batches and single size specifications, the efficiency of slicing with a wire saw is very high.

EDM and laser cutting belong to direct thermal processing, which can be used for cutting with complex shapes. However, the cutting efficiency is relatively low and the processing cost is high. Moreover, research has found that the processed surface of the sintered NdFeB magnet has a thickness of about The 15μm Nd-rich layer reduces the chemical stability of the material.

Magnet drilling requires diamond drills or lasers. Hollow drilling technology has been developed to improve material utilization. The solid cylinder dug out of the center of the product with a larger inner diameter can also be used to make other small-size products, with ultrasonic drilling. The hole method can alleviate brittle damage, which is beneficial to the processing of high-performance or thermally stable magnets with high brittleness.

Grinding wheels are divided into two types: metal-based or resin-based. The profile grinding is based on the contour of the grinding surface to make the grinding wheel base, then plated with diamond or BN powder, and modified to meet the final product requirements.

Machining will produce defects on the surface of the magnet, which will seriously affect the performance and corrosion resistance of the magnet, which is more serious for small and thin products. Therefore, it needs to be repaired by removing or repairing the surface defect layer.