What is the relationship between magnetic separator and permanent magnet?

Magnetic separators use the magnetic differences between minerals to separate them, which can improve the grade of ore, purify solid and liquid materials, and recycle waste. They are one of the most widely used and versatile machines in the industry.

Magnetic separators are widely used in mining, wood, kiln, chemical, food and other industries. For the mining industry, magnetic separators are suitable for wet or dry magnetic separation of materials such as manganese ore, magnetite, pyrrhotite, roasted ore, ilmenite, and hematite with a particle size of less than 50 mm. They are also used for iron removal and waste treatment of materials such as coal, non-metallic minerals, and building materials.

Structure and working principle of magnetic separators

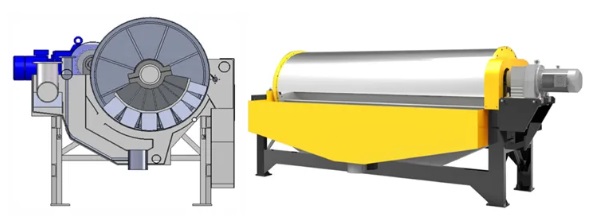

Magnetic separators (taking wet permanent magnetic drum magnetic separators as an example) are mainly composed of 6 parts: cylinder, roller, brush roller, magnetic system, tank body, and transmission part. The cylinder is welded from 2-3mm stainless steel plates, and the end cover is a cast aluminum part or workpiece, which is connected to the cylinder with stainless steel screws. The motor drives the cylinder, magnetic roller and brush roller to rotate through a reducer or directly uses a stepless speed regulation motor.

After the slurry flows into the tank through the feed box, the ore particles enter the feeding area of the tank in a loose state under the action of the water flow of the feed water pipe. Under the action of the magnetic field, the magnetic ore particles gather to form "magnetic clusters" or "magnetic chains". The "magnetic clusters" or "magnetic chains" are affected by the magnetic force in the slurry and move toward the magnetic poles and are adsorbed on the cylinder. Since the polarity of the magnetic poles is arranged alternately along the rotation direction of the cylinder and is fixed during operation, the "magnetic clusters" or "magnetic chains" produce magnetic stirring due to the alternation of magnetic poles when rotating with the cylinder. Non-magnetic minerals such as gangue mixed in the "magnetic clusters" or "magnetic chains" fall off during the turning, and the "magnetic clusters" or "magnetic chains" that are finally absorbed on the surface of the cylinder are the concentrate. The concentrate moves with the cylinder to the weakest magnetic edge of the magnetic system, and is unloaded into the concentrate tank under the action of the flushing water flow sprayed from the unloading water pipe. The non-magnetic or weakly magnetic minerals are left in the slurry and discharged from the tank with the slurry, which is the tailings.

Classification of magnetic separators

Magnetic separators can be classified in multiple ways according to different characteristics and standards. According to the strength of the magnetic field and the strength of the magnetic field force, they can be divided into:

(1) Weak magnetic field magnetic separator: The magnetic field strength on the surface of the magnetic pole is 80-120kA/m, and the magnetic field force is (3-6)×105kA2/m2. It is used to separate strongly magnetic ores;

(2) Strong magnetic field magnetic separator: The magnetic field strength on the surface of the magnetic pole is 800-1600kA/m, and the magnetic field force is (3-12)×107kA2/m3. It is used to separate weakly magnetic ores.

According to the separation medium, it can be divided into:

(1) Dry magnetic separator: Separation in air, mainly used to separate large, coarse-grained strongly magnetic ores and fine-grained weakly magnetic ores. Currently, it is also used to separate fine-grained strongly magnetic ores;

(2) Wet magnetic separator: Separation in water or magnetic liquid. It is mainly used to separate fine-grained strongly magnetic ores and fine-grained weakly magnetic ores.

In addition, it can also be classified according to the way the magnetic ore particles are selected, the direction of movement of the feed material, the method of discharging the selected products from the selection area, and the structural characteristics of the discharged magnetic products.

Magnetic circuit design and magnets of magnetic separators

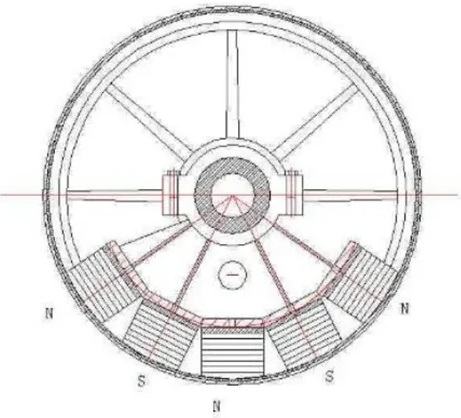

A closed loop through which magnetic flux is concentrated is called a magnetic circuit. The magnetic system of the magnetic separator needs to generate a magnetic field of a certain strength, and most of the magnetic flux in the magnetic field must be concentrated through the separation space. The height, width, radius and number of poles of the magnetic system, the magnetic potential difference between adjacent magnetic poles, the pole pitch, the ratio of the pole face width to the pole gap width, the shape of the pole and the end face of the magnetic pole, and the distance from the end face of the magnetic pole to the center of its arrangement have a significant impact on the magnetic field characteristics.

Taking the magnetic separator shown in the figure below as an example, the magnetic circuit part adopts a five-pole magnetic system. Each magnetic pole is bonded by ferrite and NdFeB permanent magnet blocks. It is fixed to the magnetic guide plate with a screw through the center hole of the magnetic block. The magnetic guide plate is fixed to the axis of the cylinder through a bracket. The magnetic system is fixed, while the cylinder can rotate. The polarity of the magnetic poles is arranged alternately along the circumference, and the polarity is the same along the axial direction. The roller made of stainless steel non-magnetic material is placed outside the magnetic system. The non-magnetic material is used to prevent the magnetic lines from entering the selection area through the cylinder and forming a magnetic short circuit with the cylinder. The part of the tank body close to the magnetic system should also be made of non-magnetic material, and the rest should be made of ordinary steel plates or hard plastic plates.

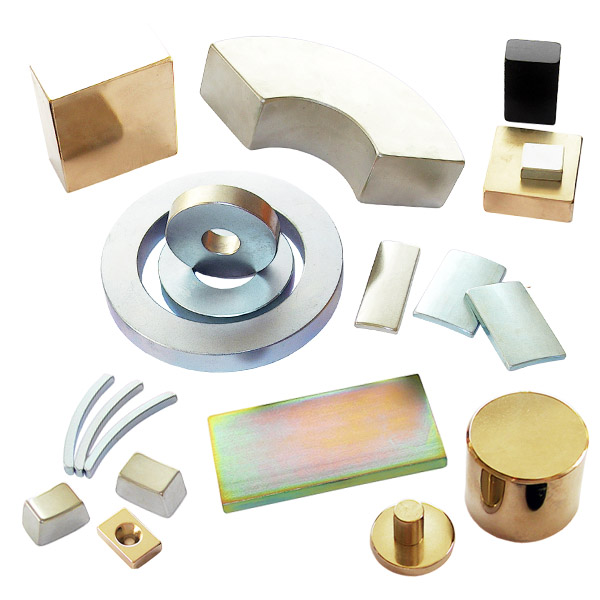

For permanent magnetic separators, permanent magnets are the most important components, and the quality of permanent magnets determines their performance characteristics. Permanent magnets for magnetic separators are generally made into certain sizes (for example, length × width × height = 85 × 65 × 21 mm), so they are usually called permanent magnet blocks or simply magnet blocks. Permanent magnetic materials that can be used to make magnetic separators include permanent ferrites, aluminum nickel cobalt, iron chromium cobalt and manganese aluminum iron, samarium cobalt permanent magnetic materials, and neodymium iron boron permanent magnetic materials. At present, the mainstream permanent magnetic materials used in domestic magnetic separation equipment are mainly permanent ferrites (strontium ferrite, barium ferrite), followed by neodymium iron boron permanent magnetic materials.

Neodymium Magnets Ferrite Magnets

In the design of magnetic system, it is necessary to judge which permanent magnetic material to use according to the specific conditions of various aspects. The influencing factors can be summarized into the following aspects:

1. Magnetic field strength: A constant magnetic field must be generated in the specified working space. The strength of this magnetic field determines which permanent magnetic material needs to be used. The magnetic properties of NdFeB permanent magnets are much higher than those of ferrites.

2. Requirements for magnetic field stability, that is, the influence and adaptability of permanent magnetic materials to environmental factors such as temperature, humidity, vibration and impact

3. Mechanical properties, such as the toughness, flexibility and compression strength of the magnet;

4. Price factors